PhAEdRA Project, Study on innovative modular control systems for electromechanical actuators aimed at the all electric aircraft market. Axis 1, action1.1.3. – National Operational Program “Enterprise and Competitiveness” 2014-2020 ERDF. “Funded as part of the Union’s response to the COVID-19 pandemic.”

PhAEdRA project (Modular Electromechanical Actuation Platform for an all electRic Aircraft) comes from Italsystem wide experience in the design and development of avionic systems and from different market needs gathered during more than 25 years of activity in the aeronautic field.

PhAEdRA project foresees the implementation of a modular platform usable, together with a dedicated test bench, for an efficient production of customizable control products, according to the Model Base Design (MBD) paradigm, in order to create innovative modular mechatronic systems with high flexibility. The devices developed within the PhAEdRA platform are compliant with aeronautical reliability standards and certifiable up to DAL A.

The Model Base Design approach is essential for guaranteeing the modularity of the system and reduce the integration, development and certification time of the final product. The HW platform consists of several modules, integrated with each other to provide the final product (EACU):

- Power modules (PDU – Power Drive Unit): development of standard modules that can be connected to each other to achieve the driving powers required by the final application. The current project is able to provide three sizes of a standard 1KW PDUs which, when suitably combined, allow the creation of all combinations of power drivers up to 3kW;

- A PSM Power Supply module for managing different DC voltages used in aeronautical systems (28V and 270V);

- CMM digital command modules configurable in a standard way that can be connected to each other for creating the basic avionic architectures of the COM/MON type;

- Two back-plane to allow interfacing with the EMA and avionics using interchangeable communication modules; this for enabling, during the configuration phase, the inclusion of the main aeronautical buses requested by the customer (ARINC429, CAN BUS, etc.);

- A standard modular case for different configurations (with particular focus on the thermal design);

- A Module for health monitoring functions based on state-of-the-art algorithms (measurement of electrical parameters, vibrational checks, etc.)

Below are various views of the assembled ECU prototype:

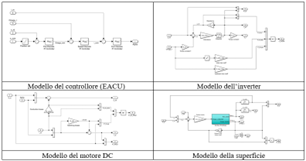

In addition, the PhAEdRA platform provides for the integration with a Simulink blocks SW platform (Toolchain Mathworks), usable by the customer for the development of its own control application with the MBD approach and the automatic production of compatible code (auto-coding) with the HW platform.

The SW platform is composed by:

- Standard actuator models for the controller design phase;

- Standard control algorithms (PID, FOC, etc.) for control routines development;

- Communication libraries for state-of-the-art avionics standards implementation;

- Health Monitoring and Prognostics Routine;

|

|

The project ended on 12/31/2023 with the realization of a final demonstrator.

Test rig designed and built by Italsystem for the qualification of the device allows to verify various configurations of the PhAEdRA platform, in combination with different types of actuators, and to apply a controlled load in order to simulate the different actuator’s typical torques depending on various flight phases and different applications (aerodynamic surface control, landing gear, etc.).

Italsystem Test rig also permits to carry out fatigue tests and verify the reliability of the designed heath-monitoring system.

|

|

Project ended on 12/31/2023